I built one Ratio kit but found the hinge for the arm, and the push-rod to operate it, unsatisfactory.

Low-cost options for the mast/post, to experiment with an internal push-rod are:

1.7mm square carbon-fibre (CF) tube (1mm diam. bore) - currently awaited.

1/16" square brass tube (0.88mm inside) - bought in UK.

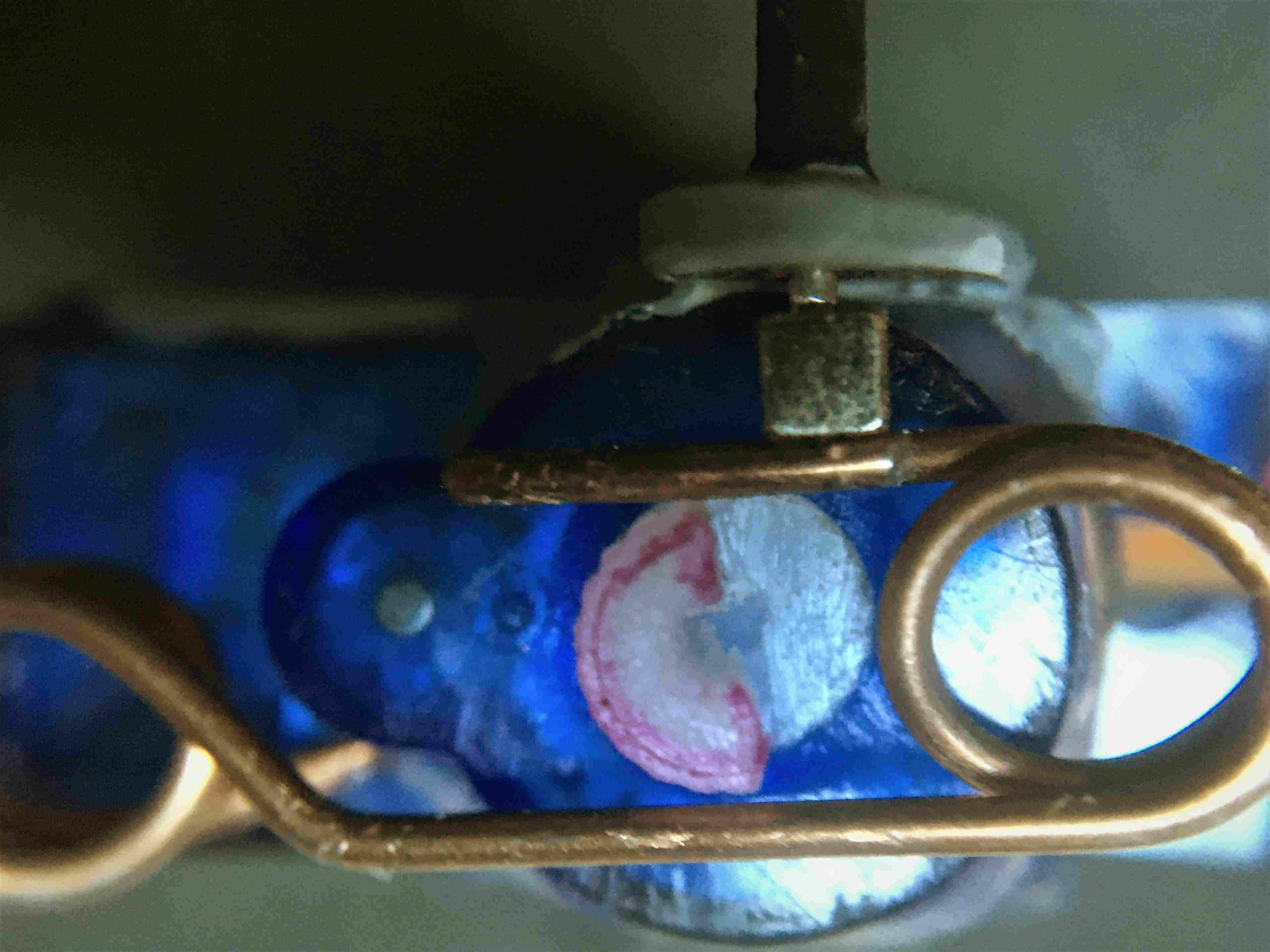

Observing magnets - particularly this cluster of 2mm cubes - it struck me how they naturally "hinge" against one-another. These ideas came together in this (Free)cad design.

- The square tube has a notch filed into the side near the top, leaving enough material to support the decorative top.

- A tiny non-magnetic shelf has to be soldered/glued to the side of the mast, just below the notch. The shelf and the bottom of the notch need to slope at about 15 degrees. It can probably be made of the same material as the mast.

- At the end of the shelf is soldered/glued a 2mm length of steel wire as a "stop" probably the same material as the push-rod, though piano wire is tough to work with.

- On the shelf rests a 2mm cube magnet, pole left and right as shown here. One pole sticks to the stop at the edge of the shelf.

- The push-rod is a straight piece of steel wire, probably 0.8mm diam. As this comes up the tube it tilts the magnet through about 40degrees, sticking to the right-hand pole.

- The signal arm is cut from card, coloured, and glued to the side of the magnet.

- With the right dimensions the cube just clears the top and side of the notch yet remains over the push-rod - not allowing the rod to slip up past the magnet.

- Note that there is no "horn" on the servo. The servo shaft is cut away to become a semicircular cam. The cut could be deeper for more "throw", and the corn

- The cam follower is a weak spring (prototyped from 0.9mm diam copper-plated steel "craft" wire). It is firmly anchored around the cylindrical servo gearbox with hot-melt glue. The end touching the cam is doubled back and has a cube magnet sitting on it which grips the bottom of the main push-rod. The cam-follower's shape is such that the magnet moves close to a vertical line, no twisting - though it may thus be over-complicated.